Enhancing Construction Projects with Structural Steel Fabrication Techniques

Understanding Structural Steel Fabrication

What is Structural Steel Fabrication?

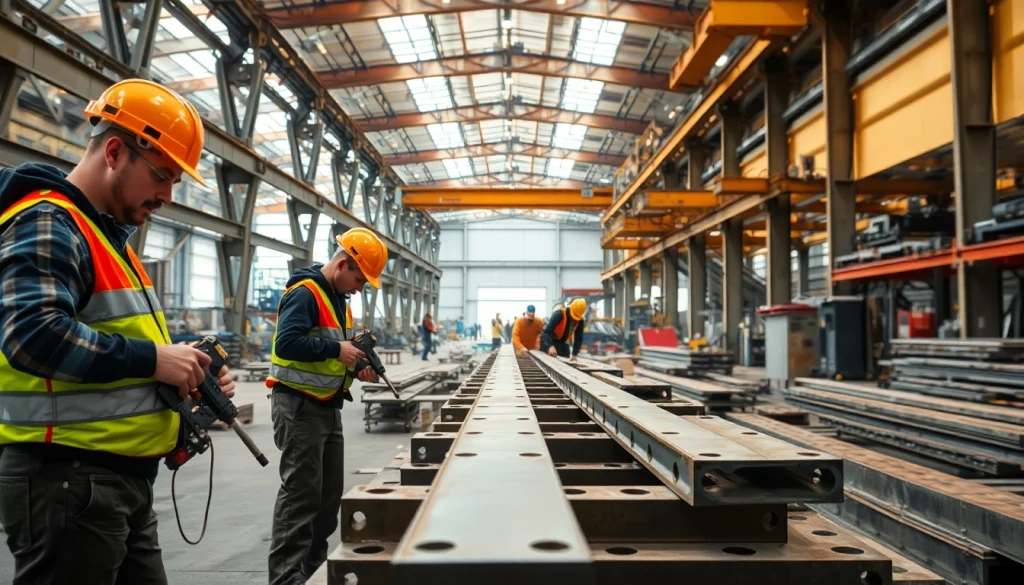

Structural steel fabrication is the process of transforming raw steel into structural elements that can be used in construction and manufacturing projects. This intricate procedure includes cutting, welding, and assembling steel sections to create beams, frames, and other essential components. The end products are capable of supporting building structures and items crucial to specific engineering needs. A critical aspect of structural steel fabrication is that it adheres to precise measurements and specifications, ensuring robustness and functionality in various applications.

The significance of this process is evident in its widespread use across many construction sectors. Engineered with durability and resilience in mind, fabricated steel offers advantages not found in other building materials. From residential projects to large-scale commercial developments, the role of structural steel is pivotal. For those seeking insights and services related to structural steel fabrication, understanding its core processes and applications is essential.

Key Processes in Structural Steel Fabrication

The fabrication of structural steel involves several key processes that work together to produce high-quality steel structures. These processes include:

- Cutting: This is the initial step where large steel sheets or beams are cut to specified sizes. Techniques such as flame cutting, plasma cutting, or sawing are often employed, depending on the thickness and type of steel.

- Shaping: After cutting, the steel goes through shaping processes, including bending and forming, to meet design specifications. This stage often utilizes hydraulic presses or rolls to create curves, angles, or other specialized shapes.

- Welding: Welding is a crucial step where various steel components are joined together to form a solid structure. Different welding methods such as MIG, TIG, or arc welding may be used, depending on the job requirements.

- Coating: To enhance the durability and longevity of the steel, protective coatings are applied. This can include galvanizing, powder coating, or painting to prevent rust and corrosion.

- Assembly: Once all components are finished, they are assembled into larger structural pieces. This is typically done in a controlled environment, allowing for greater precision in craftsmanship.

Importance of Precision in Fabrication

Precision in structural steel fabrication cannot be overemphasized. Small inaccuracies in measurements can lead to significant safety and stability issues in constructed buildings. The impact of precision is reflected in:

- Structural Integrity: Correctly fabricated steel components ensure that structures can withstand loads and stresses they will face during their lifespan.

- Cost Efficiency: Precise fabrication minimizes material waste, reducing costs associated with rework or additional materials.

- Safety Standards: Compliance with industry standards and regulations relies heavily on accurate measurements and specifications, significantly influencing overall building safety.

- Project Timelines: Accurate fabrication speeds up construction timelines, enabling timely project completion and reducing downtime.

Applications of Structural Steel Fabrication

Residential Construction and Design

In residential construction, structural steel fabrication plays a critical role in creating strong, durable frameworks that support homes. From steel beams that replace traditional wooden structures to steel trusses that enhance roof designs, the versatility of steel allows for innovative architectural solutions. Increasingly, homeowners are opting for steel-framed homes due to their fire resistance, termite prevention, and longevity compared to traditional materials.

Commercial Building Frameworks

The commercial building sector is one of the primary beneficiaries of structural steel fabrication. High-rise buildings, warehouses, and shopping centers rely on robust steel frameworks for their structural integrity. The use of fabricated steel allows for larger open spaces without the need for many internal supports, providing flexible designs for retail and office environments. Additionally, the strength-to-weight ratio of structural steel contributes significantly to the efficiency of commercial builds, allowing designers to maximize usable space.

Industrial Applications of Structural Steel

Structural steel fabrication is foundational in various industrial applications, from manufacturing plants to infrastructure projects. In the manufacturing sector, steel is used for frames, silos, and industrial shelving, ensuring the safety and functionality required for heavy machinery and equipment. Infrastructure projects such as bridges, beams, and rail systems rely on high-quality steel fabrication to support the demands of national transportation networks, demanding both precision and strength.

Choosing the Right Fabrication Service

Evaluating Fabrication Quality Standards

When selecting a structural steel fabrication service, evaluating quality standards is crucial. Look for compliance with international standards such as ISO 9001 for quality management and AWS certifications for welding quality. Additionally, inquire about the company’s history, client references, and their experience with specific projects similar to what you envision to ensure they align with your needs.

Key Questions to Ask Your Fabrication Provider

Before deciding on a fabrication service, it’s essential to ask the right questions to assess their capability and fit for your project. Consider asking:

- What processes do you use to ensure quality control during fabrication?

- Can you provide examples of past projects similar to mine?

- What is your typical turnaround time for projects of this scope?

- How do you handle unexpected challenges during fabrication?

The Role of Technology in Steel Fabrication

Technology is revolutionizing structural steel fabrication through advanced machinery and software solutions. The adoption of CNC (Computer Numerical Control) machines enables precise cutting and shaping, reducing errors and wastage. Additionally, Building Information Modeling (BIM) facilitates enhanced collaboration among engineers, architects, and contractors, ensuring that all parties work from the same accurate digital blueprint. Embracing these technologies promotes efficiency and quality in the fabrication process.

Common Challenges in Structural Steel Fabrication

Tackling Design Limitations

Design limitations can pose significant challenges for structural steel fabrication. Complex architectural designs may lead to difficulties in material sourcing or fabrication precision. To tackle these limitations, close collaboration with architects during the design phase is paramount. Through iterative design reviews and adjustments, the feasibility of complex designs can be validated before fabrication begins.

Mitigating Supply Chain Issues

Supply chain disruptions can result in delays and increased costs during the fabrication process. To mitigate these risks, identify reliable suppliers and establish strong relationships with multiple vendors. Implementing a just-in-time inventory approach can also help manage material availability without overcommitting resources. Flexibility in scheduling can enable quicker responses to unexpected delays.

Ensuring Compliance and Safety

Safety and regulatory compliance are non-negotiable in structural steel fabrication. Regularly reviewing and updating safety protocols helps ensure that workers are adequately trained and equipped to handle materials and machinery. Moreover, maintaining compliance with local building codes and regulations demands attention throughout the project lifecycle, from initial fabrication to final installation.

Future Trends in Structural Steel Fabrication

Advancements in Fabrication Technology

As technology evolves, advancements in fabrication technology shape the future of structural steel. Robotics and automation are poised to play a larger role, increasing efficiency while reducing human error. Additive manufacturing, such as 3D printing of steel components, is also gaining traction, enabling complex geometries and decreased material use.

Sustainability in Steel Manufacturing

Sustainability is becoming increasingly significant in steel fabrication, driven by the need for environmentally friendly construction practices. Trends lean towards using recycled steel and developing energy-efficient practices throughout the fabrication process. Companies are investing in green technology and practices to reduce their carbon footprint and improve overall sustainability.

Preparing for Industry Changes

The structural steel fabrication industry is continuously evolving, driven by market demand and technological advancements. Keeping pace with these changes involves ongoing education and adaptation. Engaging in continual learning opportunities, attending industry conferences, and maintaining subscriptions to relevant publications help fabrication companies stay ahead of emerging trends and developments.

FAQs about Structural Steel Fabrication

What is structural steel fabrication?

Structural steel fabrication involves cutting, shaping, welding, and assembling raw steel into components like beams and frames for construction projects.

What industries use structural steel fabrication?

Structural steel fabrication is widely used in residential construction, commercial buildings, industrial facilities, and infrastructure projects like bridges.

How do I choose a fabrication service?

Evaluate their quality standards, ask for references, review past projects, and inquire about their experience with similar work to ensure reliability.

What are common challenges in fabrication?

Challenges include tackling design limitations, mitigating supply chain issues, and ensuring compliance with safety regulations and industry standards.

How is technology improving steel fabrication?

Technology enhances precision and efficiency through CNC machines, automation, and software like BIM, contributing to error reduction and collaborative design.